As you know, joints are cut in new concrete floors to control cracking. As a fresh concrete slab hardens, it reduces in volume and shrinks. When this shrinkage is restrained by the slab’s contact with the sub-grade, adjoining structures, or reinforcement within the concrete, tensile stresses develop within the slab. And while a concrete floor is very strong in compression, its tensile strength is relatively low. The result of this internal tensile stress is cracking of the concrete.

As you know, joints are cut in new concrete floors to control cracking. As a fresh concrete slab hardens, it reduces in volume and shrinks. When this shrinkage is restrained by the slab’s contact with the sub-grade, adjoining structures, or reinforcement within the concrete, tensile stresses develop within the slab. And while a concrete floor is very strong in compression, its tensile strength is relatively low. The result of this internal tensile stress is cracking of the concrete.

The most widely used method to control cracking in concrete slabs is to place joints in the slab at specific locations that create weakened areas where the concrete can crack in a straight line. This produces an aesthetically pleasing appearance since the inevitable crack takes place under the joint, below the finished concrete surface.

Unfilled joints are especially vulnerable to damage and tend to “spall” under the impact from hard wheeled traffic. Damaged joints result in a bumpy floor surface that can cause:

- Unnecessary wear and tear on material handling equipment such as tow motors, scissor lifts, and carts

- Equipment driver fatigue

- Loss of product

- Chemical contamination of the slab and sub-base when oils/chemicals are spilled and seep into open joints

THE SOLUTION

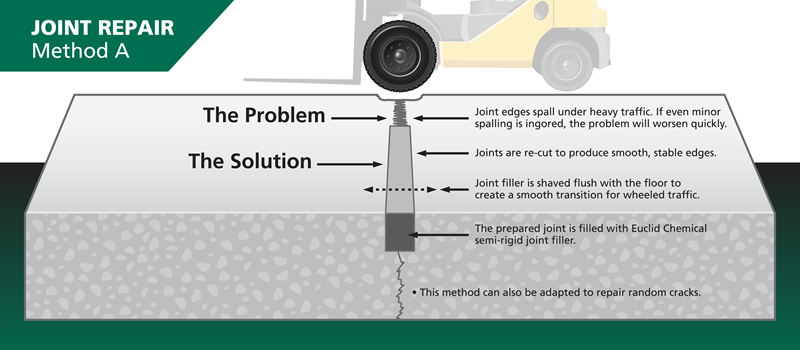

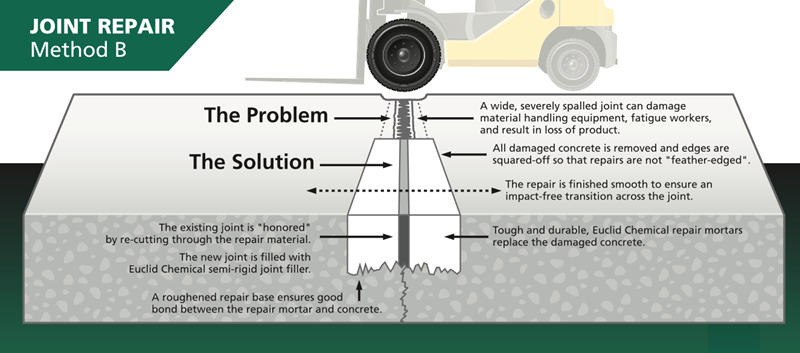

The size and cost of floor joint repairs can be kept to a minimum if the damage is detected and repaired at an early stage. Regular inspections should be made to check that any existing joint filler is doing its job to protect and maintain joint edges. If damage has been allowed to progress beyond the scope of re-filling joints, it will be necessary to reconstruct the joint itself. This is done with our heavy duty, fast curing repair mortars that are specifically intended for industrial floor use. As shown below, using Joint Repair Method A, edge spalling of mildly damaged joints can be corrected to produce a smooth, seamless floor. If more serious damage has occurred, joints will need to be fully reconstructed by using Joint Repair Method B. Both processes have been specifically developed for use in operational industrial facilities and warehouses with no need to shut down or remove inventory.

Problem - Hard wheeled traffic impacts against unfilled or unprotected joint edges, causing spalling.

Solution - Any existing, damaged joint filler is removed, joints are cleaned, and fast-curing joint filler material is installed. Warehouse traffic experiences smooth transition across joint.

Recommended Products - QWIKjoint Joint Fillers

Problem - Wide, spalled joints are experiencing major damage due to continued hard-wheeled impact.

Solution - All damaged concrete is removed and replaced with durable concrete repair mortar, followed by re-cutting and filling of joints. Floor becomes smooth and impact-free.

Recommended Products - QWIKjoint Joint Fillers • E3 Epoxy Grouts • Express Repair • Versaspeed 100/LS100 • Euco-Plate HD • Duralflex Fastpatch

Jennifer Crisman is the Director of Marketing Services at Euclid Chemical. She can be reached at jcrisman@euclidchemical.com.