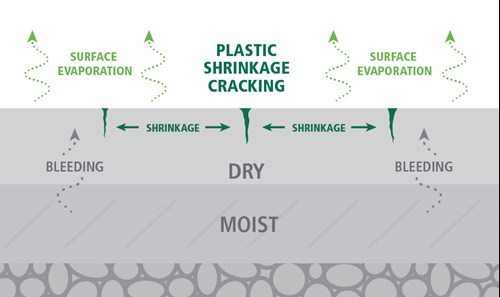

When placing concrete and cementitious concrete repair mortars, especially in hot and dry weather, evaporation rate is one of the most critical factors to take into consideration. The evaporation rate is the rate at which moisture is being lost from the concrete or mortar surface, which affects a few elements of a concrete or repair mortar placement. If the evaporation rate is too high, water is leaving the surface too rapidly, and creates difficulty during finishing operations. Equally important is that a high evaporation rate during placement and initial curing greatly increases the likelihood of plastic shrinkage cracking in the concrete surface. Plastic shrinkage cracks leave a concrete surface vulnerable to the future intrusion of water and chlorides and leave the surface with an overall unpleasant appearance.

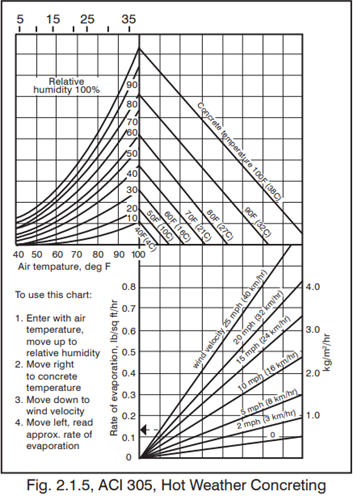

Evaporation rate is a function of relative humidity, concrete temperature, air temperature, and wind velocity at the time of placement. Here is a brief summary of how each of these properties affect the evaporation rate:

- The lower the relative humidity, the higher the evaporation rate

- The higher the concrete temperature, the higher the evaporation rate

- The higher the air temperature, the higher the evaporation rate

- The higher the wind velocity, the higher the evaporation rate

These relationships are summarized in the adjacent "five point" chart from ACI 305, “Guide to Hot Weather Concreting”, which aids in calculating approximate evaporation rates.

Plastic shrinkage cracking becomes a strong possibility when the rate of evaporation exceeds 0.2 lb/ft2/hr (1.0 kg/m2/hr), and measures to control and lower the evaporation rate should generally be considered if it exceeds 0.1 lb/ft2/hr (0.5 kg/m2/hr). Euclid Chemical manufactures several products to assist in mitigating evaporation rate-related problems.

EUCOBAR

Eucobar is designed to be used as an evaporation retardant and finishing aid on concrete surfaces of all types. When sprayed over fresh concrete or repair mortars, Eucobar forms a monomolecular film that prevents rapid moisture loss from the concrete surface. It is easy to use, requiring only the addition of water before spray application. Eucobar is especially effective when concreting or repair operations must be performed in direct sun, wind, high temperatures, or low relative humidity.

Diamond Clear VOX

Diamond Clear VOX is a VOC compliant, water-based acrylic curing and sealing compound. This product provides a quality cure to freshly placed interior or exterior concrete, while assuring total resistance to yellowing from ultraviolet exposure. Diamond Clear VOX promotes proper hydration of cement in new concrete by preventing rapid loss of moisture. Used as a sealer, Diamond Clear VOX helps concrete repel water and gives surfaces a semi-gloss appearance.

The National Ready-Mix Concrete Association’s guide CIP-12, “Hot Weather Concreting”, is an excellent source for more information on how to successfully place concrete and repair mortars in hot weather. Visit our page hosting all NRMCA Concrete in Practice (CIP) guides: NRMCA CIP's